Carbon-fiber-reinforced plastic (CFRP) has the advantages of light weight and high strength, and is widely employed in various industrial products, such as aerospace, advanced ships, new cars, wind turbine blades, pressure vessels and high-speed centrifuges. Defects and damages occurred in CFRP structures in the process of manufacturing and using will affect the reliability of materials, endanger the safety of equipment, and even cause catastrophic accidents. Using nondestructive testing technology to find defects in CFRP structures in time is an important method to prevent accidents.

Electromagnetic testing technology has the advantages of non-contact, fast imaging, and high resolution. It is suitable for inspection of various conductive structures. Although CFRP is also conductive, its electrical conductivity is anisotropic and much lower than that of metal materials, and CFRP structures are mostly three-dimensional curved surfaces. So there is still a lack of applicable non-destructive testing methods at present.

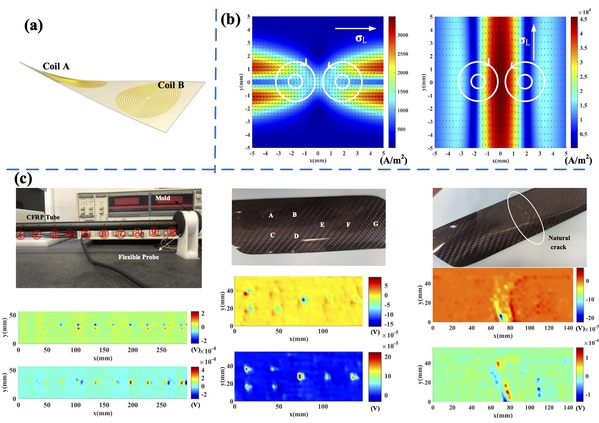

To solve the problem, SIST Assistant Professor Ye Chaofeng’s group has recently designed a flexible probe with front-end differential setting specifically for nondestructive inspection of curved CFRP structures that can obtain high-quality electromagnetic images at high frequencies. Their achievement was recently published in Composites Part B-Engineering in an article entitled “Flexible ECT probe with front-end differential setting for inspection of curved CFRP structures”.

The probe contains a pair of high-frequency flexible coils that can be bent to fit any curved surface. During detection, the two coils are excited at the same time, and the induced voltage difference is measured through the front-end differential setting, which effectively suppresses common mode interference in high-frequency detection.

In view of the anisotropic characteristics of the electrical conductivity of CFRP, the research team established an anisotropic three-dimensional electromagnetic field calculation model to study the distribution of induced currents in the carbon fiber samples. The research team used a prototype probe built by themselves to carry out the inspection and imaging of cylindrical CFRP samples with artificial defects, curved surfaces with artificial cracks and curved samples with natural impact defects. The experimental results showed that the probe can effectively detect tiny defects on the curved CFRP structures. This means that the proposed probe can has broad application prospects.

Third year Ph.D. candidate of SIST Zhang Na, SIST master student of the Class of 2021 Peng Lei and third year master student Tao Xinchen participated in the research, Prof. Ye is the corresponding author. This research work was supported byShanghai Science and Technology Commission.

(a) an effect drawing of the flexible probe with front-end differential setting; (b) simulation results: the distributions of eddy currents in materials with different electrical conductivity directions; (c) experimental samples and images of the result

沪公网安备 31011502006855号

沪公网安备 31011502006855号